Coal Forge Hood, Simple & Inexpensive

Inexpensive to build out of recycled material. Works as good as an expensive hood!

This basic system allows for a reasonable sized pile of green coal on both the chimney side of the firepot and the opposite sides of the firepot leaving room for the coke trough down the middle of the firepot.

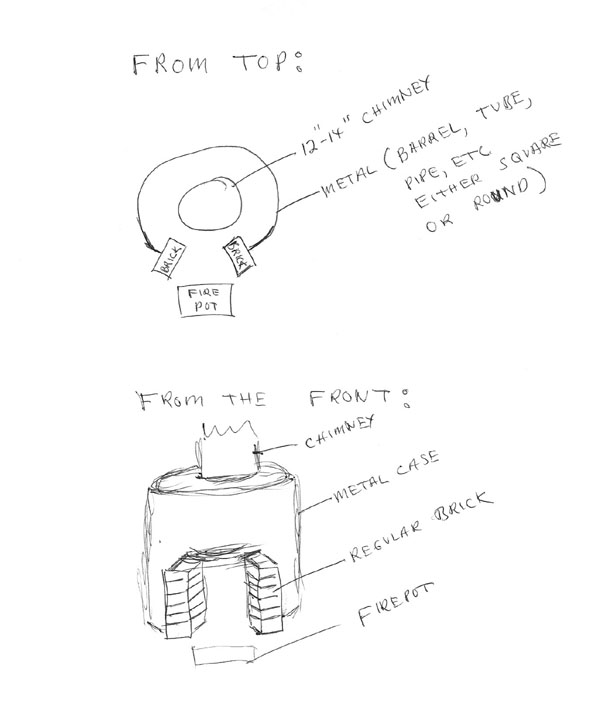

The Metal Case can be any shape: round (30 to 55 gal. drum?), square, rectangular, oval. Size of the case is not important other than it should be large enough to accommodate the brick with a little space on the sides and behind the brick.

Any kind of low cost brick can be used and can be just stacked or they can be mortared in place. If after a few years they deteriorate somewhat, just replace them. They will last much longer than thin sheet steel.

The opening would be 6 bricks high. The bricks will be from 14” to 16” high depending on if mortar is used or not. An opening of that height will allow for a pile of coal 6 to 8 inches high, between the bricks, and still have space above it for the smoke to exit.

Note that the bricks are set at an angle so that the opening is wider in front and is narrower in the back. The opening at the back of the brick should be 10 to 11 inches wide. Most rectangular firepots are about 15” long, therefore the front spacing of the brick will be about 15 to 16 inches. Even if the firepot is round, make the opening front of the brick about 15” wide in order to leave space for a pile of coal.

Sheet steel could be used instead of the bricks to funnel the heat and smoke from the firepot to the 10 inch wide chimney opening.

The front opening hole cut in the case would be 20 inches wide if standard 3.5 inch wide brick are used. Each side of the opening in the case touches the bricks in the middle of the side of the bricks. Lay out the bricks and case on a concrete floor, with chalk if necessary, to help get the measurements right.

The front of the bricks should be even (just touch) with the chimney side of the firepot (see picture). The front of the hood would be approx. 4 to 5 inches from the chimney side of the firepot. The bricks guide the smoke and heat to and up the chimney.

A piece of metal can be placed across the top of the bricks to further help the smoke and fire be guided up the chimney.

The chimney should be at least 12 inches in diameter (could be square or rectangular, although smoke travels up a round chimney better than any other shape)(see Forges). A 14 inch chimney will draw better and 16 inches would be better than 14 inch.

The bricks serve 3 main purposes:

- To keep the metal case from deteriorating too fast from the effects of the fire. They are easily replaced.

- To guide the smoke/fire from the firepot into a smaller opening. A smaller opening helps the chimney to draw as it is gulping less cool air. See sizing below.

- Between the bricks is a readily accessible place, on the table, for a pile of green coal. Making a trough down the middle of the fire pot (to place the iron) is much easier if coal is piled on both sides of the firepot rather than just one side. Also, you are making coke on 2 sides of the fire pot rather than just one. This angled brick configuration was successfully used on many old brick and stone forges.

I have seen many recently made side draft forges where the hood is next to the firepot and a narrow opening approx. 10 inches. Those style of forges make it difficult to pile coal on the chimney side of the fire pot (lack of space - width and height of the opening).

Approximate size of the opening 10” X 16” = 160 square inches

Size of a 12” round chimney = 113 square inches

Ratio of opening to chimney size = 1.4 X

Size of a 14” round chimney = 154 square inches

Ratio of opening to chimney size - 1.1 X

The smaller the ratio, the better the forge chimney will draw. Exceeding 1. X usually doesn’t draw well and requires additional ventilation in the shop to remove the smoke that gets into the work area.

Forge chimneys do not always follow the same rules that apply to gas appliance chimneys. Typically in a forge chimney, the larger the chimney the better the draw!